The advantages and precautions of using the hot stamping process in the packaging box

Hot stamping is a lithographic printing process that uses heated image molds or stamping molds to transfer metal foil or pre-dried ink to the surface of the packaging box. Usually the process of bronzing is to use a bronzing machine to heat the bronzing mold, and then press the aluminum foil onto the surface. Hot stamping is a very versatile and accurate printing method, which can be used for product packaging in almost all industries. The following is a brief overview of some of the main advantages and precautions of the bronzing process.Advantage 1

Hot stamping is also a clean and very effective process. Since the hot stamping machine uses metal foil rolls or pre-dried ink, the packaging box manufacturer can avoid the mixing of liquid ink and no ink residue.

Advantage 2

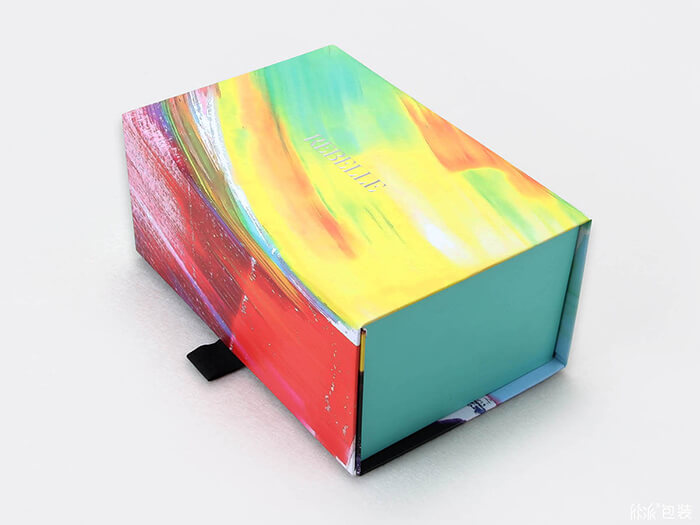

Hot stamping is a general term for a process, hot stamping does not mean that the color that is stamped on is gold. The material of bronzing paper is also divided into many colors, the most common ones are gold, silver, laser gold, laser silver, black, red, white and so on. You can choose the appropriate bronzing color according to the design of the box.

Advantage 3

The bronzing effect is very beautiful and the pattern is clear. The surface presents a metal-like texture. It can play a finishing touch and highlight the design in the packaging box. It can be applied to the logo and name.

Precautions

1. The pattern lines of the bronzing should not be too thin, not less than 0.15mm, and the text of the bronzing should not be too small. Otherwise, there will be burrs, unclear and other phenomena. If you need to print high-definition very small fonts and very fine lines, you can use the screen printing process.

2. The finished product after bronzing needs to avoid friction between the products, otherwise it will cause scratches on the text and patterns after bronzing.

3. If ordinary bronzing is applied to the fabric, it will easily cause the problem of fabric wrinkles because it needs to be heated. This phenomenon can be avoided by using cold wave.

Hot stamping is a very common process in the packaging industry. The correct use of hot stamping in the packaging box can help you win the attention of more customers and enhance your brand image.

English

English Español

Español Português

Português Pусский

Pусский Français

Français Deutsch

Deutsch 日本語

日本語 한국어

한국어 Italiano

Italiano عربى

عربى